Digital twins are revolutionizing industries by creating virtual replicas of physical assets. From IoT integration to complete control over production, discover the key trends shaping the future of this technology in 2025.

Introduction

What’s up ahead for Digital Twin solutions

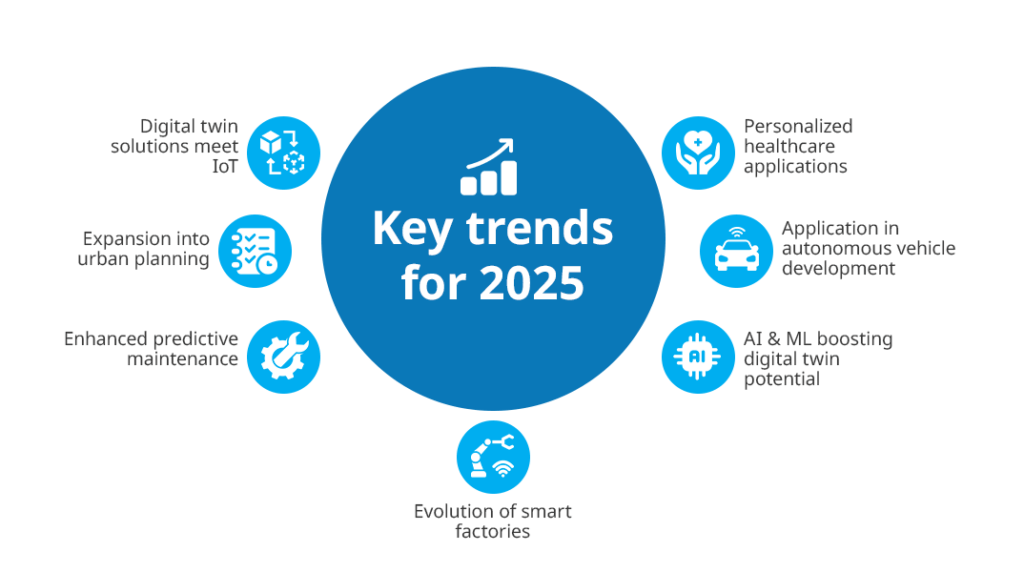

With 2025 around the corner, what’s next for digital twins? Let’s explore several key trends shaping the future of this tech:

Digital twin solutions meet IoT: The dynamic duo

When digital twins are paired with the Internet of Things (IoT), they become even more powerful. By embedding sensors in physical assets, digital twins can gather real-time data that leads to more accurate simulations and informed decision-making.

Industries like manufacturing and healthcare are already using this integration to boost efficiency and improve patient outcomes. A strong use-case is found in Asset performance X (APX), which enhances operational efficiency by combining IoT sensors, AI-driven analytics, and real-time monitoring. By creating digital twins of assets, the solution continuously compares actual performance with expected outcomes. This allows for the uncovering of inefficiencies and offering of actionable insights. The result? Optimized business operations, prevented downtime, and enablement of data-backed decisions to reduce costs and enhance asset reliability. Can you imagine the possibilities for your business?

Expansion into urban planning

Urban planners are increasingly turning to digital twins to manage and model city infrastructures. These virtual models provide a more dynamic way to visualize urban environments, optimize traffic, monitor energy usage, and improve emergency responses. Cities like Singapore and Helsinki have embraced this technology to enhance the liveability of their urban spaces.

Enhanced predictive maintenance through digital twin solutions

Predictive maintenance is one of the most practical applications of digital twins. By forecasting equipment failures before they happen, companies can reduce downtime and lower maintenance costs. Industries such as Rolls Royce in aviation are utilizing digital twins to monitor the health of their assets. This ensures operational continuity and safety.

Personalized healthcare applications

In healthcare, digital twins are being used to create personalized models for patients. These virtual replicas simulate individual health scenarios, helping doctors tailor treatment plans more effectively. However, ethical considerations regarding data privacy and accessibility remain.

AI & ML boosting digital twin potential

Combining digital twins with AI and ML algorithms enhances their predictive capabilities. These technologies analyze vast amounts of data to provide insights and optimize performance. For instance, for Unilever, AI-driven digital twins help predict production bottlenecks and suggest improvements that lead to better overall equipment effectiveness (OEE).

Application in autonomous vehicle development

The automotive industry is leveraging digital twins to develop autonomous vehicles. By using virtual models, manufacturers can simulate and test self-driving cars in a risk-free environment, speeding up development and improving safety. Companies like Tesla and Waymo are leading the way in this space.

Evolution of smart factories

Digital twins are essential to the rise of smart factories, where real-time monitoring and optimization of manufacturing processes are the norm. This results in increased efficiency, reduced waste, and higher product quality. As industries adopt this technology, the smart factory model is becoming increasingly popular.

Challenges and considerations

Despite their transformative potential, digital twins come with some challenges. Integrating data from multiple sources into cohesive virtual models is often complex, especially for organizations using legacy systems.

High development and maintenance costs can also be a barrier, as implementing digital twins requires significant investment in technology and expertise. Furthermore, security and privacy concerns are critical, with real-time data flows posing risks of cyber breaches, particularly in sensitive industries like healthcare and defense.

Addressing challenges with Asset Performance X

To tackle the challenges of implementing digital twin technology, Asset Performance X (APX) provides a comprehensive solution that simplifies processes, enhances security, and supports scalability. APX leverages advanced tools like the OmniConnect™ Data Cloud platform, which hosts digital twins and includes pre-built models based on physics and machine learning. These tools make it easier for organizations to optimize asset performance while overcoming integration complexities.

APX addresses data integration challenges by using open and adaptable digital twin technologies, allowing seamless connection with multiple data sources. The platform’s cloud-based design also enhances data security and privacy by enabling efficient storage, sharing, and visualization of information, mitigating cybersecurity risks.

For organizations concerned about scalability, APX’s infrastructure is designed to grow alongside their needs, ensuring that expanding digital twin models can be effectively managed without straining resources. By addressing these critical pain points, Asset Performance X empowers businesses to unlock the full potential of digital twin technology, driving efficiency, reliability, and operational success.

Conclusion

The future of digital twin technology is full of promise. As advancements in IoT, AI, and data analytics continue, digital twins will only get smarter and more accessible. Companies that embrace this tech early on will have a serious competitive edge.

Do you see digital twins impacting your industry in the years to come? If so, talk to our experts, and learn how you too can leverage digital twin solutions for your business operations.