Unlock your manufacturing potential with Omniconnect™ Data Cloud, seamlessly integrating IT/OT for peak efficiency and informed decision-making.

Modern organizations operate in two different worlds: the traditional OT (operational technology) and the most recent IT (information technology) side. The integration between the two enables organizations to transfer information seamlessly from OT processes to their digital spaces. About 70–80% of industrial companies have already invested, or are interested in connecting their IT/OT systems as part of the IoT deployment.

This article explores how IT/OT convergence transforms not just data integration, but the very fabric of decision-making and efficiency in the industrial landscape.

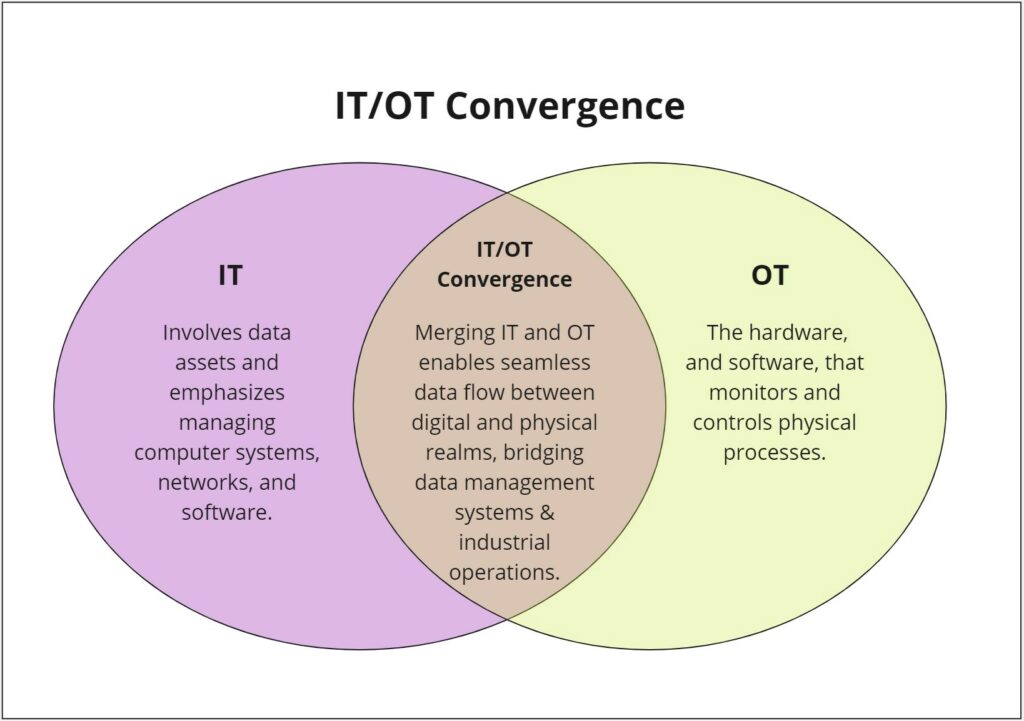

What is the difference between IT and OT?

IT includes using physical hardware such as computers, storage, networking devices, infrastructure, and procedures to create, process, store, secure and make use of electronic data.

OT, meanwhile (often from the realm of manufacturing and industrial environments), is about things like supervisory control and data acquisition (SCADA) systems. When IT and OT converge, it can open up a whole new world of possibilities for businesses worldwide.

What is the IT/OT convergence and why do we need it?

Now the question arises: What IT/OT convergence, and what makes it essential for the organization? To simplify: When OT systems integrate into IT networks, the resulting union is known as the IT/ OT convergence. While the IT/OT convergence concept isn’t entirely new, many organizations have struggled with its implementation.

For instance, a CNC machining station on a factory floor might be fully digitized and connected to similar machines. However, it may be isolated from the enterprise LAN, where the business data is exchanged through spreadsheets, PDFs, reports, etc. Thus, all the status, behaviors, and outputs of that OT machine were siloed and inaccessible by the rest of the organization and therefore, unanalyzed. Fortunately, modern technology allows us to bridge this divide.

IT/OT convergence industry examples and use cases

From industry to retail, IT/OT systems can make a wide variety of business operations more efficient and more secure. Some of the most common applications of IT/OT technology are:

Manufacturing

IT/OT convergence enables cost and resource efficiency by using sales and inventory data to inform manufacturing operations. This ensures that the equipment and power consumption is optimized, plant maintenance is minimized and unsold inventory is preserved.

Utility and energy companies

Modern IT provides OT teams remote access to operational data that allows such industries as oil, gas and energy to optimize industrial asset inspections. This also included performing damage assessments and inventory tracking and distribution.

Retail

Retail employs IT/OT technology to track which products are selling where, and customer footfall aiding in the overall customer experience. As OT devices monitor product performance and revenue, retailers can access data from their different locations to adjust inventory levels, goods production, and even store hours.

IT/OT convergence benefits

There are multiple benefits that manufacturing, retail, energy, and other industrial businesses are seeing in IT/OT convergence like:

1. Enhanced inter-department collaboration:

IT/OT convergence fosters collaboration between traditionally separated IT and OT departments. This effectively integrates with shared areas of discipline garnered from a mix of technology.

2. Improved cyber-security:

By converging IT/OT systems organizations can even enhance cyber security.

3. Greater visibility:

It also improves the overview and organization of processes, as well as data collection and archiving for audits. This integration ensures that all aspects of the business are transparent and easily monitored.

4. Improved automation:

With IT/OT convergence, OT systems gain the ability to transmit real-time factory maintenance data. It improves automation and visibility across distributed OT environments, leading to more efficient operations and proactive maintenance.

5. Optimized energy usage:

Converging IT and OT systems allows for more efficient use of energy and resources. OT systems can be better aligned with actual product needs, reducing waste and improving overall efficiency.

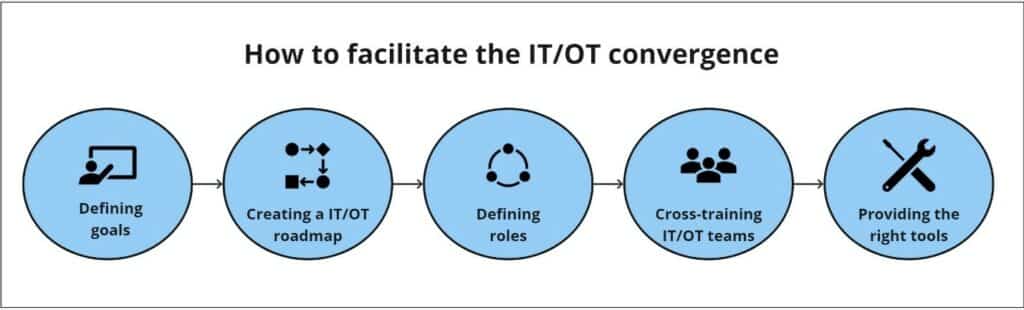

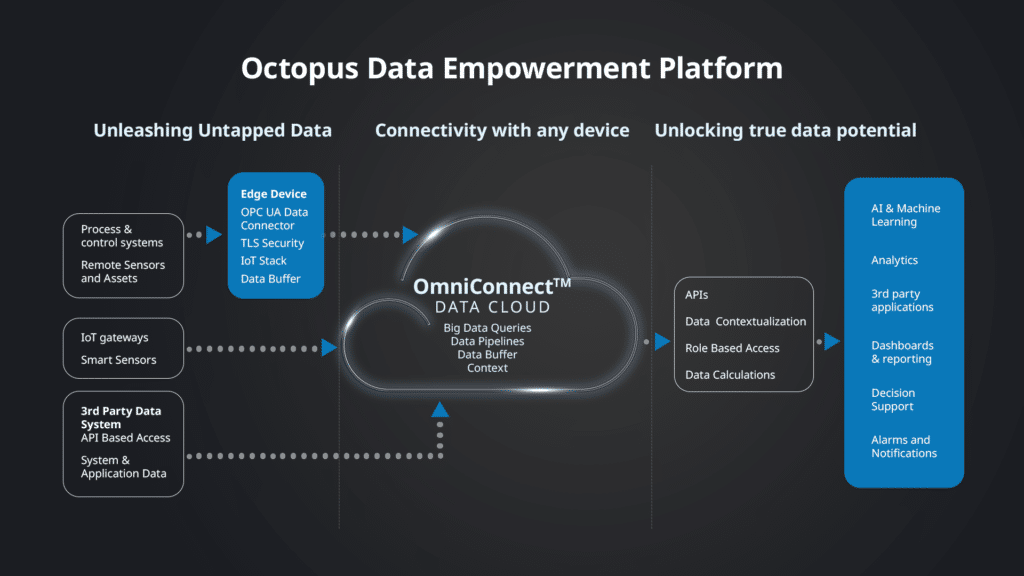

Facilitating the IT/OT convergence in your enterprise

In the landscape of IT/OT convergence for businesses, a critical factor is the availability of tools that facilitate seamless integration, notably cloud platforms, and OmniconnectTM Data Cloud platform Octopus Digital empowers organizations to navigate this transition with confidence. It seamlessly collects data from diverse sources, such as third-party devices, IoT sensors, remote sensors, process and control systems. This unified data is then stored in a centralized capable of managing both structured and unstructured data efficiently.

This synergy enables advanced predictive maintenance, machine learning techniques and AI algorithms to provide calculated insights that facilitate data-driven business decisions. Octopus Digital is the trusted partner for comprehensive IT/OT solutions that drive innovation, increase productivity and bring tremendous cost savings over time, within the industrial sector, giving you the freedom to pursue IT/OT convergence with confidence. Talk to us today and start your journey.