Manufacturing operations are experiencing a revolutionary boost in productivity. With a forecasted growth in revenue of US$ 325.80 bn by 2024, the industrial IoT market sees rapid adoption of smart manufacturing technologies. One after another, manufacturing companies are opting for digital transformation through platform such as OmniconnectTM Data Cloud in smart manufacturing. Through the convergence of IT/OT manufacturing data, efficiency and effectiveness of both systems is enhanced. Furthermore, it fuels better decision-making and optimized operational processes, powered by critical data.

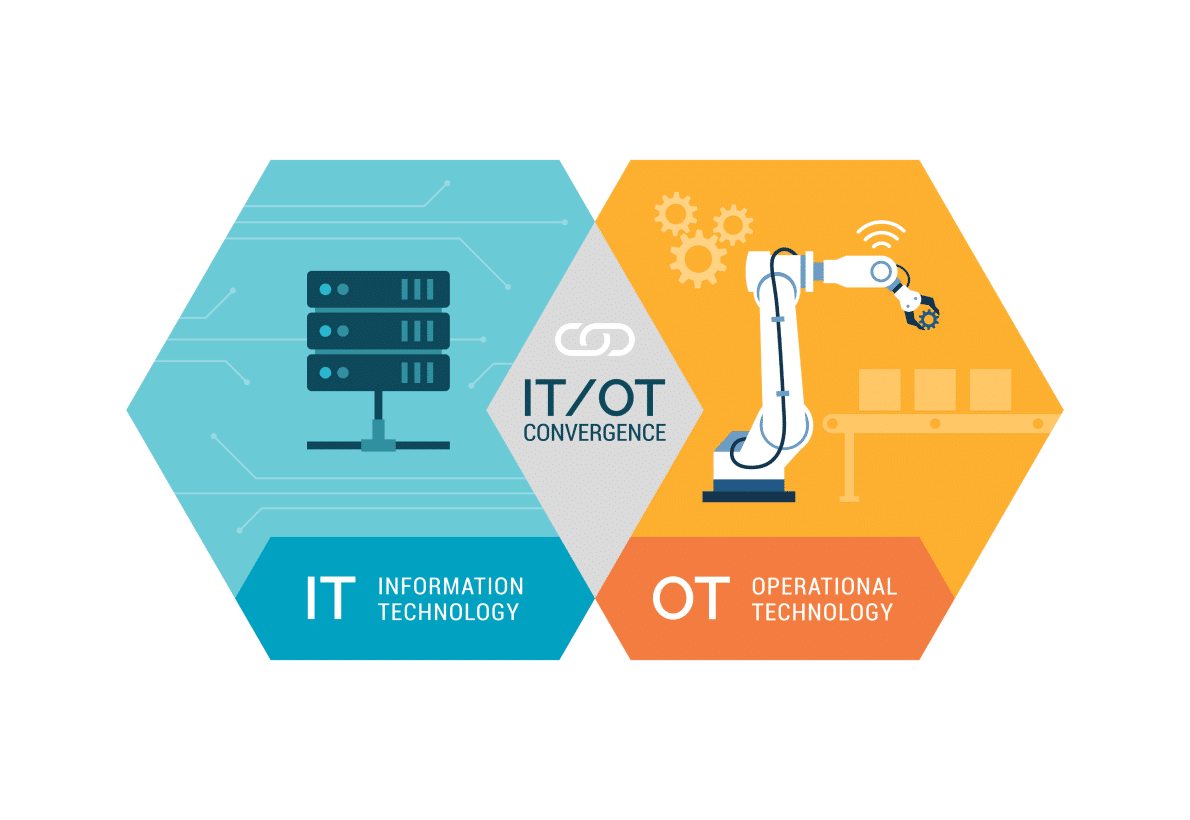

What is IT/OT Convergence?

Operational Technology (OT) consists of a combination of hardware and software, which works at controlling, managing, and overseeing physical equipment and processes. It utilizes technologies including Supervisory Control and Data Acquisition (SCADA) and Industrial Control Systems (ICS) for automation, supervision, and management of industrial activities. Information technology (IT) constitutes the manufacturers’ information technology stores, which processes, analyses, and acts on data gathered from operations. IT (Information Technology) provides the information that is used to make decisions, while OT (Operational Technology) drives actions.

IT and OT operate in silos, as their processes, language, and priorities all differ. This means that there exists a gap in communication and coordination between both. Manufacturers will only avail the benefits of digitization once these silos are removed, legacy technology is modernized and IT/OT convergence takes place.

What is Omniconnect™?

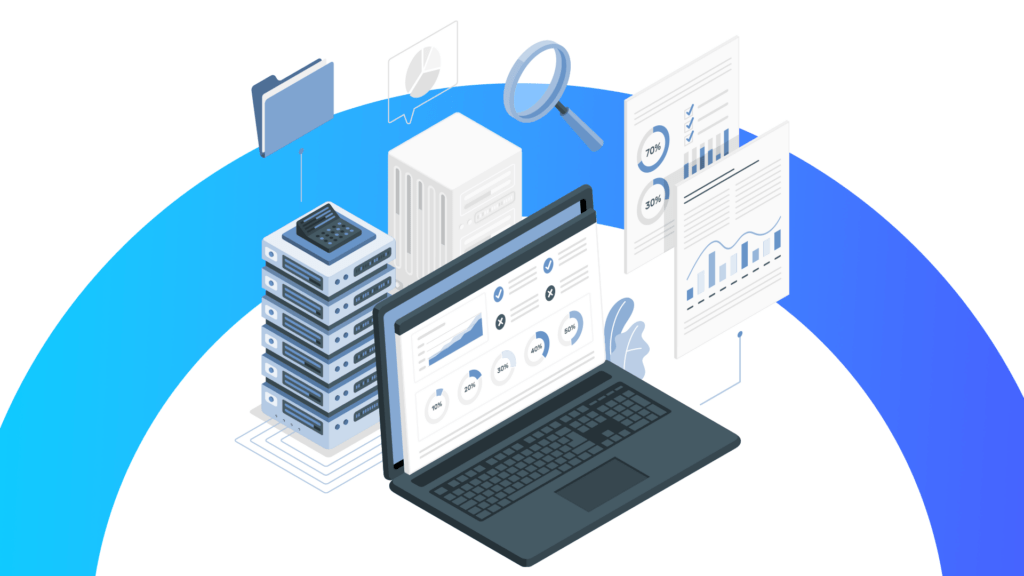

A key driver of propelling this IT/OT Convergence is Industrial Internet of Things (IIoT) technologies, like OmniconnectTM Data Cloud. By the creation of a hierarchal and linear structure that integrates throughout the architecture, it gathers and processes real-time data. Through this SaaS-based, cloud-native IT/OT convergence platform, manufacturers gain the ability to analyze their disparate manufacturing data. This unified platform enables them to access all data sources in one place. This facilitates data-driven business decisions for effective planning, monitoring, predictive analytics, prescriptive maintenance, and risk management.

OmniconnectTM Data Cloud collects data from diverse sources, such as third-party devices, IoT sensors, remote sensors, processes and control systems. It then stores everything in a centralized repository —OmniConnect™ data lake that can store all unstructured and structured data.

Once this back-end integration links OT floor data with systems, the unstructured and structured data can then be readied for analysis. Access to a comprehensive dataset empowers analytics and applications to collaborate seamlessly, enhancing operations. This synergy leverages cloud analytics, control, remote monitoring, energy management, and other optimization strategies to implement advanced predictive maintenance techniques effectively.

Benefits of integrating Omniconnect™ Data Cloud

- By digitizing manufacturing operations, companies meet the latest standards of Industry 4.0.

- Real-time learning and prediction maximize ROI by utilizing effective planning, predictive analytics, predictive maintenance, risk management, and AI-driven optimization.

- Omniconnect™ Data Cloud allows for ease of accessibility of data and insights, providing access to data anywhere from the internet.

- Automation and visibility are improved because the OT system integration transmits to OmniconnectTM real-time production data.

- Omniconnect™ Data Cloud allows remote monitoring.

- Decision-making is improved due to the important data generating valuable insights, enhancing operational efficiency, and mitigating risks.

Omniconnect™ Data Cloud in action

- Challenge:

A major textile manufacturer faced the challenge of monitoring its coal-fired electricity generation facility and enabling utility distribution. They needed a comprehensive solution to monitor the power plant KPIs. This was to be achieved by gaining visibility into OT data of diverse assets. Furthermore, they were to overcome the absence of historical data, and to optimize product quality.

- Solution:

OmniconnectTM Data Cloud created data pipelines and data lakes to monitor real-time OT data and integrate with IT data for enhanced performance insights. The team explored the actual versus expected performance of the assets, focusing on power generation and consumption for plant utilities. Using Omniconnect™ Data Cloud, they created dashboards to display and highlight the KPIs. They extracted data from the Oracle ERP cloud and integrated business and IT data to drive comprehensive insights.

The team specially focused on efficiency monitoring, including asset performance and the reduction of theoretical losses. As a result, tangible improvements were observed in plant performance. Furthermore, OmniconnectTM data cloud optimized product pricing and strategic planning, contributed to a more streamlined and effective operational framework.

- Impact:

Foremost among the benefits of OmniconnectTM data cloud was the heightened visibility of data, particularly regarding utility distribution to each plant. We successfully identified significant inefficiencies and initiated internal processes and managed to reduced them subsequently.

The advent of OmniconnectTM acts as a propellant in the journey of manufacturing operations toward industry 4.0 standards. By bridging the gap between IT and OT through its robust convergence platform, OmniconnectTM data cloud maximizes efficiency and productivity for manufacturers.

If you are looking to unlock to the complete potential of your manufacturing operations through OmniconnectTM, book a demo.